Microcement Underfloor Heating Compatibility: Complete Technical Guide

Expert guide to combining microcement flooring with underfloor heating systems for optimal performance and energy efficiency in London and Surrey homes

The combination of microcement flooring with underfloor heating represents one of the most sophisticated and comfortable flooring solutions available for modern homes. This pairing offers the aesthetic appeal and durability of microcement with the luxury and energy efficiency of radiant floor heating, creating spaces that are both beautiful and supremely comfortable.

Understanding the technical requirements, installation considerations, and performance characteristics of microcement over underfloor heating systems is crucial for successful projects. This comprehensive guide explores the compatibility factors, installation procedures, and long-term performance considerations that ensure optimal results from this premium flooring combination.

Whether you’re planning a new installation or considering adding underfloor heating to existing microcement floors, this technical analysis provides the essential information needed for informed decision-making and successful project outcomes.

Understanding Underfloor Heating Systems

Types of Underfloor Heating

Different underfloor heating systems have varying compatibility characteristics with microcement flooring, and understanding these differences is crucial for optimal performance.

Electric Underfloor Heating: Electric systems use heating cables or mats installed beneath the floor surface to provide radiant heat. These systems offer precise temperature control and rapid response times, making them particularly suitable for microcement applications. The thin profile of electric systems minimizes floor height increases, which is advantageous in renovation projects.

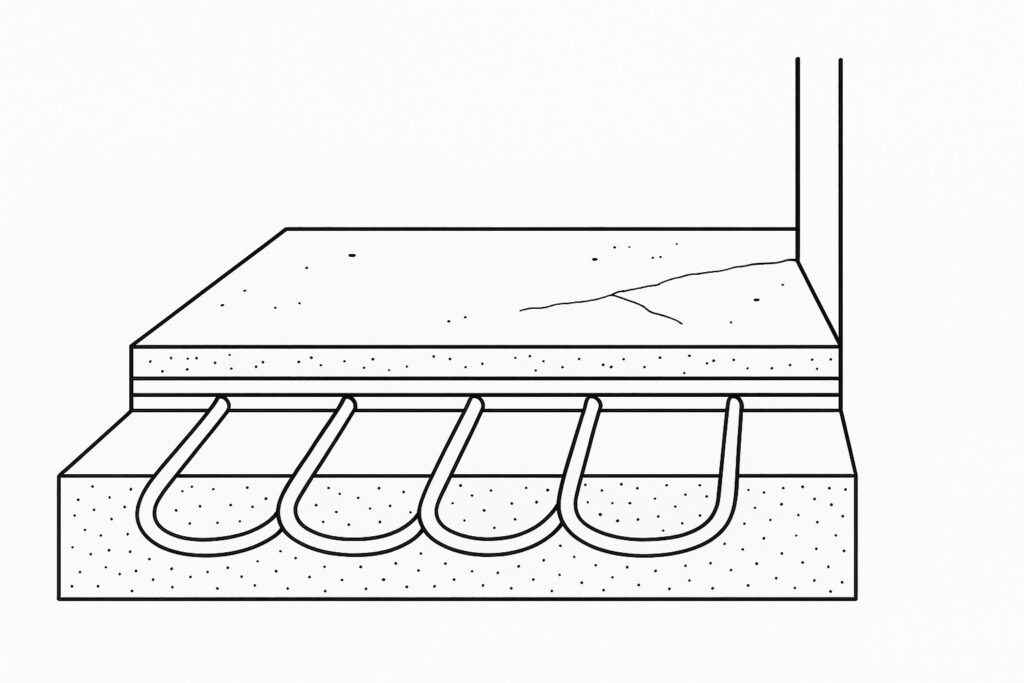

Water-Based (Hydronic) Systems: Hydronic systems circulate warm water through pipes embedded in the floor structure. These systems provide excellent energy efficiency for larger areas and integrate well with renewable energy sources. The thermal mass of water-based systems provides steady, consistent heat that complements the thermal properties of microcement.

Hybrid Systems: Some installations combine electric and hydronic elements to optimize performance and efficiency. These systems may use electric heating for rapid response in specific zones while relying on hydronic systems for primary heating in larger areas.

Thermal Performance Characteristics

The thermal properties of underfloor heating systems directly impact their compatibility with microcement flooring and overall system performance.

Heat Distribution: Underfloor heating provides even heat distribution across the entire floor surface, eliminating cold spots and creating consistent comfort levels. This even distribution is particularly beneficial with microcement, which conducts heat efficiently and maintains comfortable surface temperatures.

Response Times: Electric systems typically provide faster response times than hydronic systems, allowing for more precise temperature control. This characteristic is valuable in spaces with varying occupancy patterns or where rapid temperature adjustments are desired.

Operating Temperatures: Underfloor heating systems operate at relatively low temperatures (typically 25-35°C surface temperature), which is ideal for microcement applications. These moderate temperatures prevent thermal stress while providing comfortable heating.

Energy Efficiency: The low operating temperatures of underfloor heating systems provide excellent energy efficiency, particularly when combined with well-insulated floors. Microcement’s thermal conductivity enhances this efficiency by effectively transferring heat to the room.

Microcement Thermal Properties

Heat Conduction and Distribution

Microcement’s thermal properties make it an excellent choice for use over underfloor heating systems, providing efficient heat transfer and comfortable surface temperatures.

Thermal Conductivity: Microcement has good thermal conductivity, allowing efficient heat transfer from the heating system to the room. This property ensures that heat is effectively distributed across the floor surface without creating hot spots or temperature variations.

Thermal Mass: The thermal mass of microcement helps moderate temperature fluctuations and provides thermal stability. This characteristic works well with underfloor heating systems to maintain consistent comfort levels and reduce energy consumption.

Surface Temperature: Microcement surfaces over underfloor heating maintain comfortable temperatures that are warm to the touch without becoming uncomfortably hot. This makes the flooring pleasant for bare feet while providing effective space heating.

Heat Retention: Microcement retains heat effectively, continuing to provide warmth even after the heating system cycles off. This thermal retention improves energy efficiency and maintains comfort during heating system downtime.

Thermal Expansion Considerations

Understanding thermal expansion characteristics is crucial for preventing problems in microcement installations over underfloor heating.

Expansion Coefficients: Microcement has relatively low thermal expansion compared to many other flooring materials. This characteristic reduces stress on the installation and minimizes the risk of cracking or other thermal-related problems.

Movement Accommodation: Proper installation techniques can accommodate the minimal thermal movement that occurs with temperature changes. Expansion joints and flexible connections help manage thermal movement without compromising the installation.

Substrate Compatibility: The thermal expansion characteristics of microcement must be compatible with the substrate and heating system. Proper design ensures that all components expand and contract together without creating stress concentrations.

Long-term Stability: Microcement maintains its thermal properties over time, ensuring consistent performance throughout the life of the installation. This stability is crucial for long-term satisfaction with the heating system performance.

Installation Considerations

System Design and Planning

Successful integration of microcement with underfloor heating requires careful planning and coordination between heating system design and flooring installation.

Heat Load Calculations: Proper heat load calculations ensure that the underfloor heating system provides adequate heating capacity while operating within temperature limits suitable for microcement. These calculations consider room size, insulation levels, and desired comfort levels.

Zone Design: Heating zones should be designed to accommodate microcement installation requirements, including expansion joints and access points. Proper zoning also optimizes energy efficiency and comfort control.

Insulation Requirements: Adequate insulation beneath the heating system is crucial for efficiency and performance. Proper insulation prevents heat loss to the substrate and ensures that heat is directed upward through the microcement flooring.

Control Systems: Advanced control systems optimize the performance of underfloor heating with microcement flooring. These systems can provide precise temperature control and energy management features that enhance comfort and efficiency.

Installation Sequence

The sequence of installation activities is crucial for successful integration of microcement with underfloor heating systems.

Substrate Preparation: The substrate must be properly prepared to receive both the heating system and microcement flooring. This includes ensuring level surfaces, adequate structural support, and proper moisture management.

Heating System Installation: The underfloor heating system must be completely installed and tested before microcement application begins. This includes pressure testing for hydronic systems and electrical testing for electric systems.

Insulation and Leveling: Proper insulation and leveling compounds ensure optimal heat distribution and provide a suitable surface for microcement application. These materials must be compatible with both the heating system and microcement.

Microcement Application: Microcement application follows standard procedures with special attention to thermal considerations. Proper curing and temperature control during application ensure optimal bonding and performance.

Temperature Management During Installation

Controlling temperatures during microcement installation over underfloor heating systems is crucial for optimal results.

Curing Temperature Control: Microcement curing should occur at moderate temperatures to ensure proper chemical reactions and bonding. Extreme temperatures during curing can affect final properties and performance.

Heating System Operation: The underfloor heating system should typically remain off during microcement application and initial curing. Gradual temperature introduction after curing helps prevent thermal shock and ensures proper performance.

Environmental Conditions: Controlling ambient temperature and humidity during installation helps ensure optimal microcement curing and prevents problems such as rapid drying or condensation.

Commissioning Procedures: Proper commissioning of the combined system ensures optimal performance and identifies any issues before final completion. This process includes gradual temperature increases and performance verification.

Performance Optimization

System Efficiency Maximization

Optimizing the performance of microcement flooring with underfloor heating requires attention to both system design and operational parameters.

Temperature Settings: Optimal temperature settings balance comfort with energy efficiency. Surface temperatures of 25-28°C typically provide excellent comfort while maintaining energy efficiency. Higher temperatures may increase energy consumption without proportional comfort benefits.

Control Strategies: Advanced control strategies can significantly improve system performance. These may include weather compensation, occupancy sensing, and learning algorithms that adapt to usage patterns and preferences.

Zoning Optimization: Proper zoning allows different areas to be heated according to their specific requirements and usage patterns. This optimization reduces energy consumption while maintaining comfort in occupied spaces.

Integration with Building Systems: Integrating underfloor heating controls with other building systems such as ventilation and lighting can optimize overall energy performance and comfort levels.

Heat Distribution Enhancement

Maximizing heat distribution effectiveness ensures optimal comfort and energy efficiency from the combined microcement and underfloor heating system.

Thermal Bridging Prevention: Preventing thermal bridging ensures that heat is effectively transferred through the microcement rather than being lost to the structure. Proper insulation and installation techniques are crucial for preventing thermal bridging.

Surface Preparation: Proper surface preparation ensures optimal heat transfer from the heating system through the microcement. This includes eliminating air gaps and ensuring good thermal contact between all system components.

Thickness Optimization: Optimizing microcement thickness balances thermal performance with other requirements such as durability and aesthetics. Thinner applications generally provide better thermal response, while thicker applications may offer enhanced durability.

Edge Details: Proper edge details prevent heat loss and ensure even temperature distribution across the entire floor surface. These details are particularly important at perimeters and transitions to other flooring materials.

Energy Efficiency Strategies

Implementing energy efficiency strategies maximizes the environmental and economic benefits of the combined system.

Insulation Optimization: High-quality insulation beneath the heating system prevents heat loss and improves efficiency. The investment in superior insulation typically pays for itself through reduced operating costs.

Smart Controls: Smart control systems can significantly improve energy efficiency by optimizing operation based on occupancy, weather conditions, and energy costs. These systems can reduce energy consumption by 15-30% compared to basic controls.

Renewable Energy Integration: Underfloor heating systems work particularly well with renewable energy sources such as heat pumps and solar thermal systems. The low operating temperatures required are ideal for these efficient energy sources.

Thermal Storage: The thermal mass of microcement and the floor structure can provide thermal storage that reduces energy consumption and improves comfort. This storage effect helps maintain comfortable temperatures during heating system downtime.

Maintenance and Long-term Performance

Routine Maintenance Requirements

Maintaining optimal performance from microcement flooring over underfloor heating requires attention to both the flooring and heating system components.

Microcement Maintenance: Regular cleaning and periodic sealer renewal maintain the appearance and performance of microcement flooring. The presence of underfloor heating does not significantly change these maintenance requirements.

Heating System Maintenance: Underfloor heating systems require periodic maintenance to ensure optimal performance. This may include system flushing for hydronic systems or electrical testing for electric systems.

Control System Maintenance: Control systems require periodic calibration and software updates to maintain optimal performance. Regular maintenance ensures that efficiency and comfort benefits are maintained over time.

Performance Monitoring: Regular monitoring of system performance helps identify potential issues before they become serious problems. This monitoring can include energy consumption tracking and temperature measurement.

Troubleshooting Common Issues

Understanding common issues and their solutions helps maintain optimal performance from the combined system.

Uneven Heating: Uneven heating may indicate problems with the heating system, insulation, or microcement installation. Systematic diagnosis helps identify the root cause and appropriate solutions.

Slow Response Times: Slow system response may indicate issues with controls, insulation, or thermal bridging. Addressing these issues can significantly improve system performance and user satisfaction.

High Energy Consumption: Excessive energy consumption may indicate system inefficiencies or control problems. Energy audits can help identify opportunities for improvement and optimization.

Comfort Issues: Comfort problems may result from improper temperature settings, control issues, or system design problems. Systematic evaluation helps identify and address comfort issues.

Longevity Considerations

Ensuring long-term performance requires attention to factors that affect both the microcement flooring and underfloor heating system.

Material Compatibility: Long-term compatibility between microcement and heating system components ensures sustained performance. Quality materials and proper installation techniques are crucial for longevity.

Thermal Cycling: Repeated heating and cooling cycles can affect both microcement and heating system components. Proper design and installation minimize the effects of thermal cycling on system longevity.

Maintenance Planning: Developing comprehensive maintenance plans helps ensure long-term performance and prevents premature system degradation. These plans should address both flooring and heating system requirements.

Upgrade Considerations: Planning for future upgrades or modifications helps ensure that the system can adapt to changing requirements or technology improvements.

Cost Considerations and ROI

Initial Investment Analysis

Understanding the costs associated with combining microcement flooring with underfloor heating helps in making informed investment decisions.

System Costs: The combined cost of microcement flooring and underfloor heating is typically higher than conventional flooring and heating systems. However, the benefits in comfort, efficiency, and aesthetics often justify the additional investment.

Installation Complexity: The complexity of installing both systems together may increase labor costs compared to separate installations. However, coordinated installation can also provide efficiencies and ensure optimal integration.

Design and Engineering: Proper design and engineering are crucial for optimal performance and may represent a significant portion of project costs. This investment in design typically pays dividends in system performance and longevity.

Quality Considerations: Investing in high-quality materials and installation typically provides better long-term value despite higher initial costs. Quality installations require less maintenance and provide better performance over time.

Operating Cost Benefits

The operating cost benefits of microcement flooring with underfloor heating can provide significant long-term savings.

Energy Efficiency: The energy efficiency of underfloor heating systems can provide substantial savings compared to conventional heating systems. These savings are enhanced by the thermal properties of microcement flooring.

Maintenance Savings: The durability of microcement flooring and the reliability of quality underfloor heating systems can provide maintenance savings compared to other flooring and heating combinations.

Comfort Benefits: The superior comfort provided by radiant floor heating can allow lower thermostat settings while maintaining comfort levels. This can provide additional energy savings and improved comfort.

Property Value: The combination of microcement flooring and underfloor heating can enhance property values, providing return on investment through increased property worth.

Return on Investment Calculations

Calculating return on investment helps justify the additional costs of combining microcement with underfloor heating.

Energy Savings: Annual energy savings can be calculated based on system efficiency improvements and local energy costs. These savings typically provide payback periods of 5-15 years depending on local conditions.

Maintenance Savings: Reduced maintenance costs for both flooring and heating systems contribute to return on investment. These savings accumulate over the life of the installation.

Comfort Value: While difficult to quantify, the comfort benefits of radiant floor heating provide significant value to occupants. This value is often reflected in property values and rental rates.

Longevity Benefits: The extended life of quality installations provides value through reduced replacement costs and sustained performance over decades.

Design Applications and Aesthetics

Residential Applications

Microcement flooring with underfloor heating provides exceptional benefits in residential applications, particularly in luxury homes and renovation projects.

Open Plan Living: The combination works particularly well in open plan living areas where consistent comfort and seamless flooring enhance the sense of space and luxury. The absence of radiators or heating vents maintains clean architectural lines.

Bathroom Applications: Heated microcement floors in bathrooms provide exceptional comfort and luxury. The waterproof properties of microcement combined with the warmth of underfloor heating create spa-like environments.

Kitchen Integration: In kitchens, heated microcement floors provide comfort for extended standing periods while maintaining the durability and easy maintenance required in food preparation areas.

Bedroom Comfort: Heated floors in bedrooms provide exceptional comfort, particularly during cold mornings. The gentle warmth eliminates the shock of cold floors and enhances overall comfort.

Commercial Applications

Commercial applications of microcement with underfloor heating provide both comfort and operational benefits.

Retail Environments: Heated microcement floors in retail environments provide customer comfort while maintaining the durability required for commercial use. The seamless appearance enhances the shopping experience.

Office Spaces: In office environments, underfloor heating with microcement flooring provides comfortable working conditions while maintaining professional aesthetics. The system operates quietly without the air movement of forced-air systems.

Hospitality Applications: Hotels and restaurants benefit from the luxury and comfort provided by heated microcement floors. These installations enhance the guest experience while providing operational durability.

Healthcare Facilities: The easy cleaning and maintenance of microcement combined with the comfort of underfloor heating makes this combination suitable for healthcare applications where hygiene and comfort are priorities.

Conclusion: Optimal Integration for Modern Living

The combination of microcement flooring with underfloor heating represents the pinnacle of modern flooring technology, providing unmatched comfort, efficiency, and aesthetic appeal. When properly designed and installed, this combination delivers decades of reliable performance with minimal maintenance requirements.

Success with this sophisticated flooring system requires careful attention to design details, proper installation procedures, and ongoing maintenance. The investment in quality materials, professional installation, and appropriate controls typically provides excellent returns through energy savings, enhanced comfort, and increased property values.

For homeowners and commercial property owners in London and Surrey considering this premium flooring solution, working with experienced professionals ensures optimal results and long-term satisfaction. The technical complexity of integrating these systems makes professional expertise essential for achieving the full benefits of this advanced flooring technology.