Expert Microcement Installation London & Surrey

Microcement is an exciting and unique product that will reinvent the way you look at wall and floor finishes forever. Transform dated wall or floor finishes to a modern contemporary look . Revive that old worktop to high quality concrete top with the minimum of fuss

- Waterproof and Durable

- Broad Range of Design Choices

- Easy to Maintain

The Benefits of Micro Cement

Waterproof and Durable

Broad Range of Design Choices

Easy to Install and Maintain

Get in touch

Advantages of microcement

Waterproofing

Advanced waterproof properties create impermeable barriers that resist moisture penetration. Ideal for bathrooms, kitchens, and outdoor applications where water resistance is essential

Endless Possibilities

Microcement adapts to any surface, shape, or design vision. From floors to walls, curved surfaces to complex architectural features

Low Maintenance

Simple cleaning routines maintain appearance for years. The seamless, non-porous surface resists stains and eliminates grout lines where dirt and bacteria typically accumulate.

Minimalistic - Clean Design

Seamless surfaces and continuous finishes embody modern minimalist principles. Creates uncluttered, flowing spaces that emphasize architectural features and natural light.

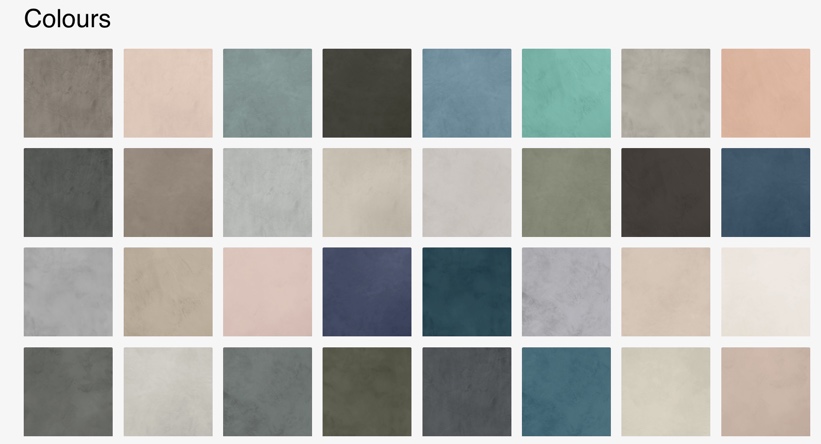

Customization

Choose from an extensive range of colors, textures, and finishes to create surfaces that perfectly reflect your personal style.

Built to Last

Engineered for exceptional longevity, microcement withstands heavy traffic, impact, and daily wear without compromising its appearance.

Sustainable Choice

Environmentally responsible material that requires minimal resources to produce and apply.

Microcement Application Process

Surface Preparation & Assessment

Foundation for Success

Thorough surface preparation is the most critical step in microcement application. The substrate must be completely clean, dry, stable, and properly assessed before any application begins.

Ceramic Tiles & Porcelain

Plaster & Gypsum Surfaces

Existing Paint Surfaces

Concrete & Cement Screeds

Primer Application & Mesh Installation

Creating the Perfect Bond

Key Information:

- Primer type depends on substrate porosity (absorbent vs non-absorbent)

- Fiberglass mesh mandatory on all floors and tiled surfaces

- Allow 30 minutes minimum drying time before next step

- Coverage rate: approximately 0.15-0.20 kg/m² for primer

Technical Notes:

- Use Primer Plus for non-absorbent surfaces (tiles, marble, terrazzo)

- Use Standard Primer for absorbent surfaces (plaster, concrete, drywall)

- Apply mesh without wrinkles or air bubbles

- Overlap mesh joints by minimum 10cm

⚠️ Note:

Do not exceed 24-hour window between primer and base coat application. Ensure complete primer coverage – missed areas will cause adhesion failure. Never apply primer in direct sunlight or high wind conditions. Protect work area from dust contamination during drying.

Base Coat Application (First Layer)

Building the Foundation Layer

Key Information:

- Apply in thin, even layers (maximum 1mm thickness)

- Work in manageable sections to maintain wet edge

- Use cross-hatch application technique for optimal coverage

Technical Notes:

- Mix only quantity needed for 30-45 minutes of work

- Use flexible steel trowel at 30-45 degree angle

- Apply with overlapping strokes to avoid lines

- Sand lightly between coats if necessary to remove imperfections

⚠️ Note:

Base Coat Application (Second Layer)

Strengthening and Leveling

The second base coat reinforces the first layer, provides additional strength, and creates a smooth, level surface for the finishing coats. This layer is crucial for achieving the final surface quality and eliminating any imperfections from the first coat.

Key Information

- Light sanding may be required to smooth imperfections

- Apply perpendicular to first coat direction for optimal coverage

- Thickness: 0.5-1mm maximum per coat

Technical Notes:

- Vacuum all dust thoroughly before application

- Check for and fill any pinholes or imperfections

- Use consistent mixing ratios for colour uniformity

- Work systematically to avoid overlap marks

⚠️ Note:

Finish Coat Application (Two Layers)

Achieving the Final Aesthetic

The finishing coats provide the final color, texture, and aesthetic appearance of the microcement surface. Applied in two thin layers, these coats create the characteristic microcement look while providing the surface that will be sealed and protected.

Key Information:

- First finish coat: focus on coverage and color uniformity

- Second finish coat: concentrate on final texture and appearance

- Each coat thickness: 0.3-0.5mm maximum

Technical Notes:

- Use rubber trowel for smoother finish, steel trowel for more texture

- Apply in random, overlapping strokes for natural appearance

- Maintain wet edge to avoid visible joints

- Final coat determines surface texture – work carefully

⚠️ Note:

Sealing and Protection

Long-term Performance Protection

The final sealing process protects the microcement from stains, moisture, and wear while enhancing the color and providing the desired sheen level. This critical step ensures long-term durability and ease of maintenance.

Key Information:

- Apply presealer first, followed by topsealer

- Two coats of each sealer type required

- Allow 24 before use

Technical Notes:

- Use high-quality synthetic rollers for even application

- Apply in thin, even coats to avoid pooling

- Sand lightly between sealer coats if needed

- Temperature and humidity affect curing time

⚠️ Note:

Ensure microcement is completely dry before sealing. Poor sealer application cannot be easily corrected. Allow full cure time before exposing to water or chemicals.